What is drop molding spunlace nonwoven fabric?

Drop-molded spunlace non-woven fabric is a kind of non-woven fabric material that has undergone special treatment. The following is its related introduction:

Material and craftsmanship

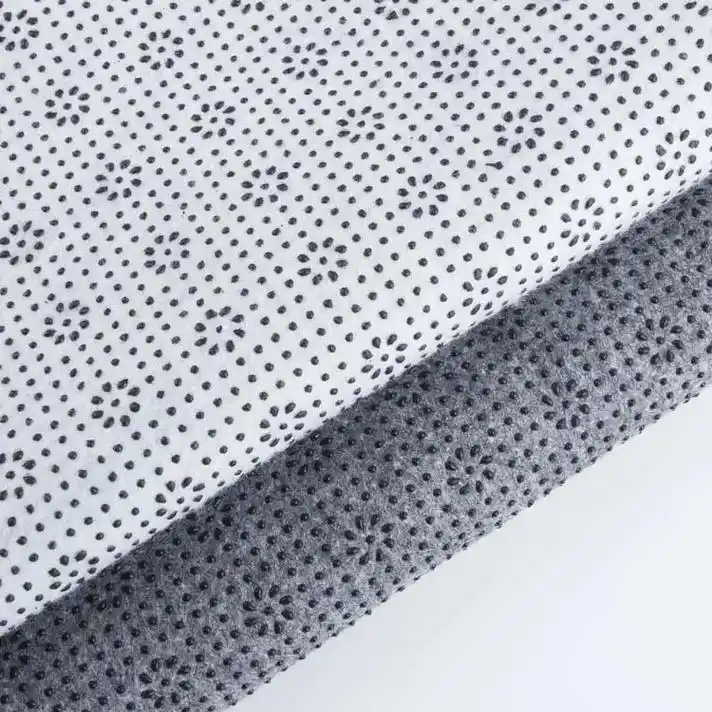

Spunlace nonwoven fabric: This is the basic material of drop molding spunlace nonwoven fabric. It is a non-woven fabric formed by combing fibers into a web and then using high-pressure water jets to entangle the fibers with each other. The non-woven fabric produced by this process features softness, breathability, high strength, good moisture absorption and other characteristics. Moreover, the fibers are evenly distributed and the hand feel is comfortable.

Drop molding treatment: Based on spunlace non-woven fabric, liquid plastic or rubber and other high-molecular materials are dropped onto the surface of the non-woven fabric through the drop molding process. The materials of drop molding usually have good wear resistance, water resistance and anti-slip properties, etc. By controlling the pattern, density and thickness of the drop molding, different functions and appearance effects can be endowed to non-woven fabrics.

Characteristics and Applications

Features: The drop-molded spunlace nonwoven fabric combines the advantages of spunlace nonwoven fabric and drop-molded materials. It retains the softness, breathability and moisture absorption of nonwoven fabric, while enhancing the wear resistance, anti-slip and water resistance of the drop-molded part. Its surface has a certain three-dimensional effect and texture, and its appearance is beautiful and diverse.

Application: This material is often used to make various products that require anti-slip, wear-resistant and waterproof functions, such as anti-slip MATS, automotive interiors, shoe materials, medical supplies, industrial filtration materials, etc. For instance, in the interior of a car, it can be used to make seat covers, floor MATS, etc., which not only provide a comfortable touch but also play a role in anti-slip and waterproof. In the medical field, it can be used to make surgical gowns, bed sheets, etc. Its waterproof performance helps prevent liquid penetration, protecting patients and medical staff.

How to choose the right drop molding spunlace non-woven fabric material?

When choosing the appropriate spunlace non-woven fabric material, multiple factors need to be considered. Here are some key points:

Clarify the purpose of use

Usage: Different uses have different requirements for material properties. If it is used to make anti-slip MATS, the anti-slip and wear-resistant properties of the material need to be given priority consideration. When used in the medical field, attention should be paid to its hygiene, breathability and water resistance, etc.

Usage environment: Consider the environmental conditions in which the material is used, such as temperature, humidity, and contact with chemical substances, etc. When used in high-temperature environments, the material needs to have good heat resistance. In a humid environment, materials with good water resistance and mold resistance should be selected.

Consider the material properties

Physical properties

Strength: This includes tensile strength, tear strength, etc. Materials with appropriate strength should be selected based on the tensile and tear forces they may withstand during actual use. For instance, the plastic-coated spunlace nonwoven fabric used in industrial filtration needs to have a relatively high tensile strength to withstand the pressure during the filtration process.

Softness: If used in products that come into contact with the skin, such as clothing and medical supplies, softness is an important indicator. Soft materials can provide better comfort.

Breathability: For application scenarios that require breathability, such as shoe materials and automotive interiors, good breathability can make users feel comfortable and prevent the accumulation of stuffiness and moisture.

Chemical properties

Chemical resistance: If the material may come into contact with chemical substances, such as when used in industrial cleaning or chemical environments, a drop molding spunlace non-woven fabric with good chemical resistance should be selected to prevent the material from being corroded or damaged by chemical substances.

Hygiene: Materials used in food packaging, medical care and other fields must comply with relevant hygiene standards, be non-toxic, odorless and have certain antibacterial properties to ensure safe use.

Analyze the drop molding process and quality

Drop molding pattern and density: Select the appropriate drop molding pattern and density based on product design and functional requirements. For example, anti-slip MATS require dense drip plastic patterns to provide a better anti-slip effect; For some decorative products that emphasize aesthetics, the drip molding patterns need to take into account their coordination with the overall design.

The quality of drop molding: High-quality drop molding should be firmly combined with non-woven fabric, have a smooth surface, and be free of defects such as bubbles and cracks. The quality of the drop molding can be evaluated by observing the sample or conducting a simple peel test to ensure that the drop molding part does not fall off or get damaged during use.

Evaluate suppliers and costs

Supplier reputation: Choose suppliers with a good reputation and strong production capabilities. They usually can provide products of stable quality and offer guarantees in terms of after-sales service and technical support. The credibility of a supplier can be evaluated by checking its qualification certificates, customer reviews, industry reputation, etc.

Cost factor: Under the premise of meeting the usage requirements, consider the cost of materials. Including the purchase price of materials, transportation cost, storage cost, etc. At the same time, the performance and service life of the materials should be comprehensively considered. Sometimes, materials with higher performance and longer service life are chosen. Although the purchase price is higher, they may be more cost-effective in the long run.

What are the advantages and main uses of drop molding spunlace nonwoven fabric?

Advantages

Excellent anti-slip performance: The drop molding process forms patterns or shapes with certain roughness and friction on the surface of non-woven fabrics, significantly enhancing the anti-slip effect of the material. It can effectively prevent objects from sliding on its surface and is suitable for various occasions that require anti-slip performance.

Soft and comfortable: Spunlace non-woven fabric itself has a soft texture. It feels comfortable when in close contact with the skin. Even after drop molding processing, it can still maintain good softness and will not cause irritation to the human body. It is suitable for products that come into contact with the skin.

Excellent air permeability: The fiber structure of spunlace non-woven fabric has good air permeability, allowing air to pass freely and enabling the skin to "breathe" without causing a stuffy feeling. Especially when used in items that come into close contact with the human body, such as clothing and household items, it can provide a comfortable user experience.

Strong hygroscopicity: It can quickly absorb moisture and keep the surface dry. This characteristic enables it to be used as a wound dressing in the medical field, absorbing wound exudate and promoting wound healing. In the field of beauty and makeup, it can quickly absorb toner and other liquids, making it convenient to use.

High strength: The drop plastic spunlace nonwoven fabric combines the strength of spunlace nonwoven fabric and the wear resistance of the drop plastic layer. It has good tensile strength, tear strength and puncture resistance, is not easy to break, can withstand certain tensile and compressive forces, and extends the service life of the product.

Strong customizable: By changing the pattern, shape, density and color of the drop molding, the personalized demands of different customers can be met, and various functions and decorative effects can be achieved. For instance, various fashionable patterns can be designed on clothing, and different anti-slip textures can be customized on anti-slip MATS according to the usage scenarios.

Main uses

Household items: It can be used to make anti-slip MATS, carpets, sofa cushions, etc. Its anti-slip performance can effectively prevent items from sliding and enhance the safety of use. The soft texture can provide a comfortable touch and enhance the comfort of household items.

Clothing and accessories: It is often used on the collar, cuffs, shoulders and other parts of clothing, serving to reinforce, prevent slipping and decorate. For instance, in some sportswear, the drop molding spunlace non-woven fabric can increase the friction between the clothes and the skin, making the clothes fit the body better and less likely to slip off. In addition, it can also be used to make shoe materials, such as insoles and inner linings, providing a comfortable foot feel and good anti-slip performance.

Medical field: It can be used to manufacture surgical gowns, medical masks, wound dressings, etc. Spunlace non-woven fabric itself has good air permeability and moisture absorption. After drop molding processing, it can increase the strength and wear resistance of the material while maintaining its original hygiene performance, which is conducive to improving the quality and safety of medical supplies.

Industrial applications: In automotive interiors, it can be used to make seat covers, instrument panel coverings, etc. It not only provides a comfortable touch but also plays a certain anti-slip role, preventing items from sliding inside the vehicle. In addition, it can also be used in industrial filtration, packaging and other fields. By taking advantage of its filtration performance and strength, it can filter liquids or gases and package some items that need protection.

Beauty and makeup: Some cotton pads, facial mask base fabrics, etc. will use drop molding spunlace non-woven fabric. It features softness, skin-friendliness and strong water absorption, which can better absorb and release toner, essence and other substances, providing good care for the skin.

Where can find factories that produce plastic-coated spunlace non-woven fabrics and products?

HYFabricsupply is a factory specializing in the research and development, production and sales of spunlace nonwoven fabrics. The main products include viscose polyester spunlace nonwoven fabric, wood pulp polyester spunlace nonwoven fabric, PP wood pulp spunlace nonwoven fabric, and ultrafine fiber spunlace nonwoven fabric. Special treatments can be carried out on spunlace non-woven fabrics, such as printing, embossing, drop molding, cutting, packaging, etc., and they can be processed according to different usage requirements. If you need to customize spunlace non-woven fabric products and items, please contact us.